Exploring Back Pressure Valve Innovations at the 138th Canton Fair 2025 in China

As the global industrial landscape evolves, the significance of back pressure valves in fluid control systems becomes increasingly paramount. The 138th Canton Fair, scheduled for 2025 in China, presents a pivotal platform for industry leaders and innovators to showcase advancements in back pressure valve technology. According to a recent market analysis by ResearchAndMarkets, the global back pressure valve market is projected to grow significantly, with a compound annual growth rate (CAGR) of 6.5% from 2023 to 2028. This trend underscores the rising demand for efficient fluid management solutions across various industries, including oil and gas, pharmaceuticals, and water treatment. The integration of smart technologies and improved materials in back pressure valve designs is set to enhance performance and reliability, making this year's Canton Fair an essential event for stakeholders eager to explore cutting-edge innovations and form strategic partnerships in this dynamic market.

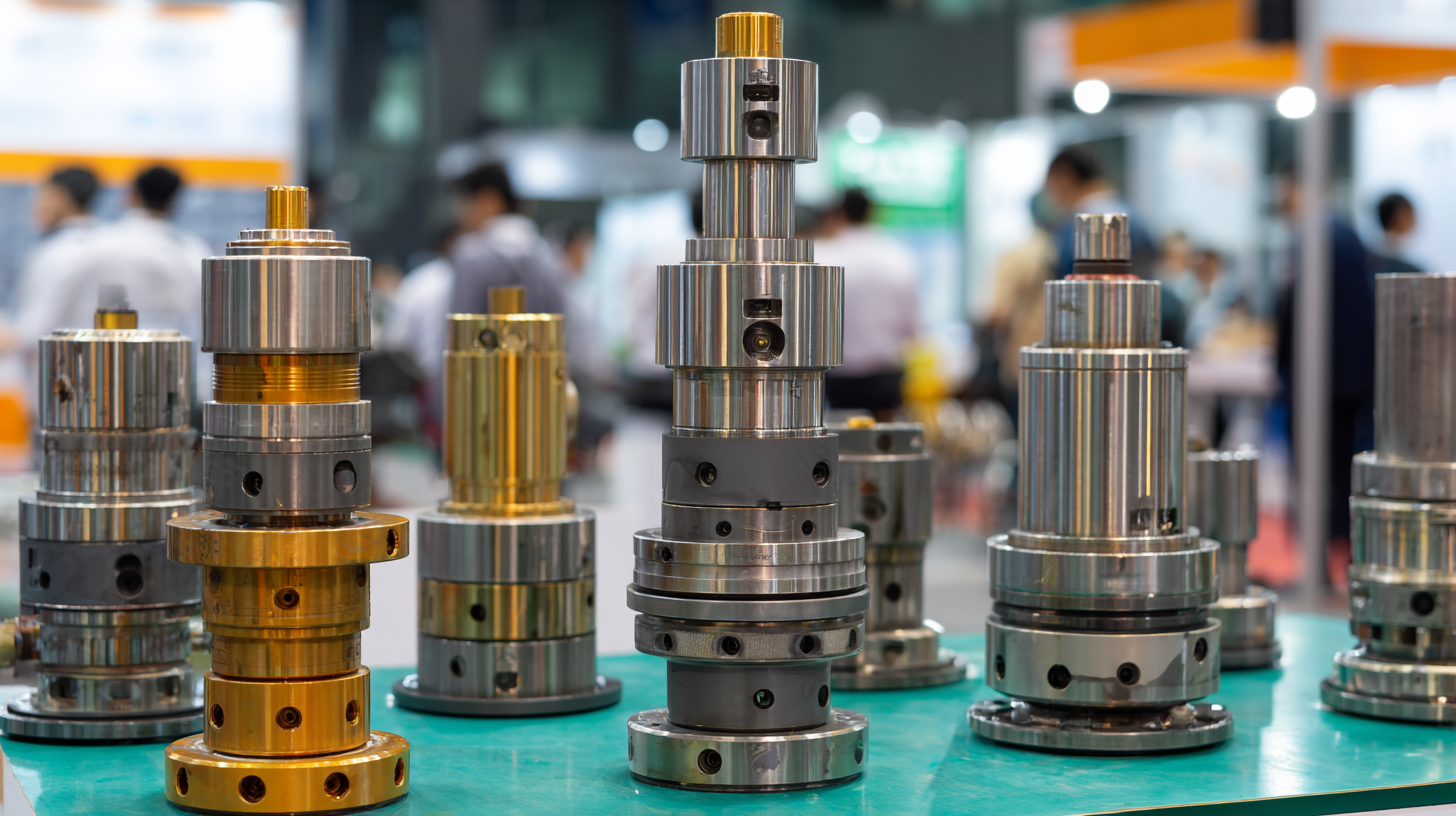

Innovative Back Pressure Valve Designs Showcased at the 138th Canton Fair

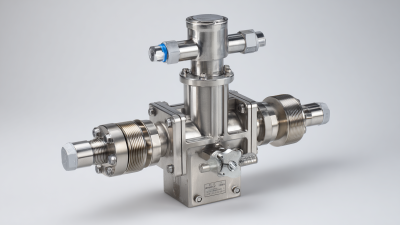

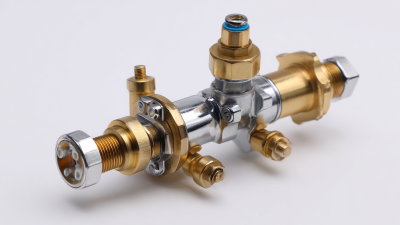

The 138th Canton Fair in 2025 is set to highlight a range of groundbreaking designs in back pressure valve technology. Industry leaders and innovators will showcase their latest advancements, emphasizing the importance of efficiency and reliability in fluid control systems. These innovative designs are not only tailored to meet the demanding requirements of various industrial sectors but also incorporate cutting-edge materials and technologies that enhance performance and durability.

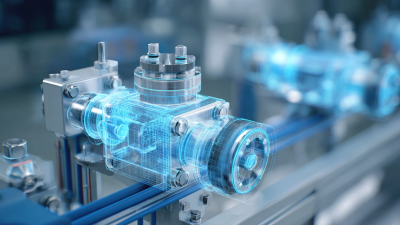

One of the standout features of this year's exhibition is the integration of smart technology within back pressure valves. Many manufacturers are now implementing IoT capabilities that allow for real-time monitoring and adjustments, significantly improving operational efficiency and safety. This new wave of products promises to revolutionize how industries manage pressure in their systems, providing solutions that are both sustainable and cost-effective. The fair serves as a crucial platform for professionals to exchange ideas and collaborate on these advanced technologies, paving the way for future innovations in fluid management systems.

Trends and Technologies Driving Back Pressure Valve Advancements

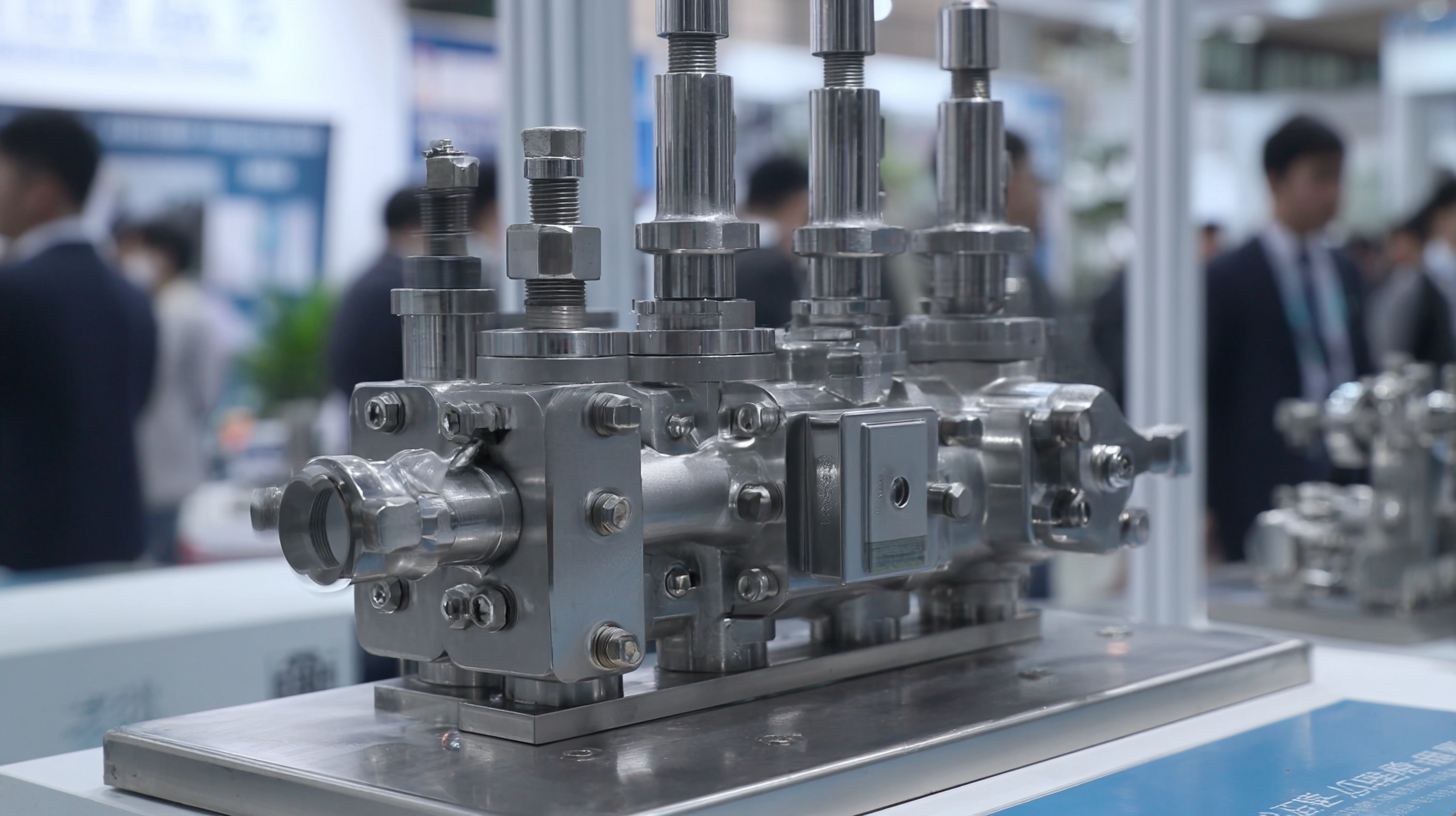

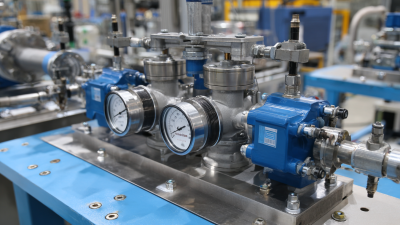

At the 138th Canton Fair 2025 in China, the focus on back pressure valve innovations is unmistakable, reflecting broader trends and technologies that are reshaping the industrial valve landscape. These advancements are not merely incremental; they embody significant leaps in technology that enhance the performance and efficiency of these vital systems. For instance, the integration of sensor technologies for monitoring hydraulic valve and system performance is paving the way for more digitally connected and responsive operations. This digitalization facilitates real-time data analysis, enabling proactive maintenance and increased operational efficiency.

Moreover, the global industrial valves market is witnessing a surge, projected to grow significantly in the coming years. Alongside this growth, the emphasis on sustainability is driving innovation, as manufacturers explore designs that reduce costs and improve biocompatibility. Techniques borrowed from the latest advancements in polymeric materials are influencing the development of valves, offering enhanced durability and reliability. As we venture further into 2025, the convergence of these trends indicates that back pressure valves will play a pivotal role in the evolution of industrial applications, significantly impacting various sectors' operational capabilities.

Global Industry Leaders in Back Pressure Valve Manufacturing at the Event

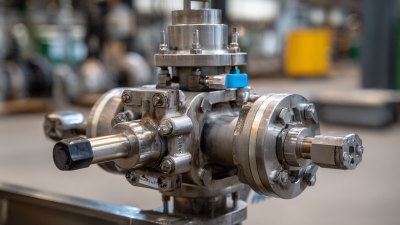

The 138th Canton Fair in 2025 promises to be a significant platform for exploring innovations in the back pressure valve manufacturing sector. Industry leaders from around the globe are anticipated to showcase their advancements, focusing on technologies that enhance efficiency and reliability in various applications. The fair will not only highlight the latest designs and materials but also pave the way for discussions on digital transformation within the manufacturing industry, emphasizing the need for manufacturers to prioritize investments in their data infrastructure.

As global supply chains continue to face challenges, the emphasis on creating resilient and efficient systems will be paramount. This is an excellent opportunity for attendees to learn about different strategies implemented by industry leaders to mitigate disruptions.

Tip: When attending industry events, always network with other professionals to gain insights into emerging trends and best practices.

Participants should also consider engaging with technology experts at the fair, who can provide valuable information on how to integrate innovative solutions into their operations.

Tip: Prepare a list of questions in advance to maximize the value of discussions with exhibitors and speakers at the event.

Networking Opportunities for Industry Professionals at the Canton Fair

The 138th Canton Fair in 2025 presents a unique opportunity for industry professionals to network and exchange innovative ideas. As one of the largest trade fairs in China, the event will attract exhibitors and visitors from various sectors, particularly those involved in the manufacturing and design of back pressure valves. Attendees will have the chance to engage with experts, gain insights into the latest advancements in technology, and discuss challenges facing the industry today.

Impact of Back Pressure Valve Innovations on Future Industrial Applications

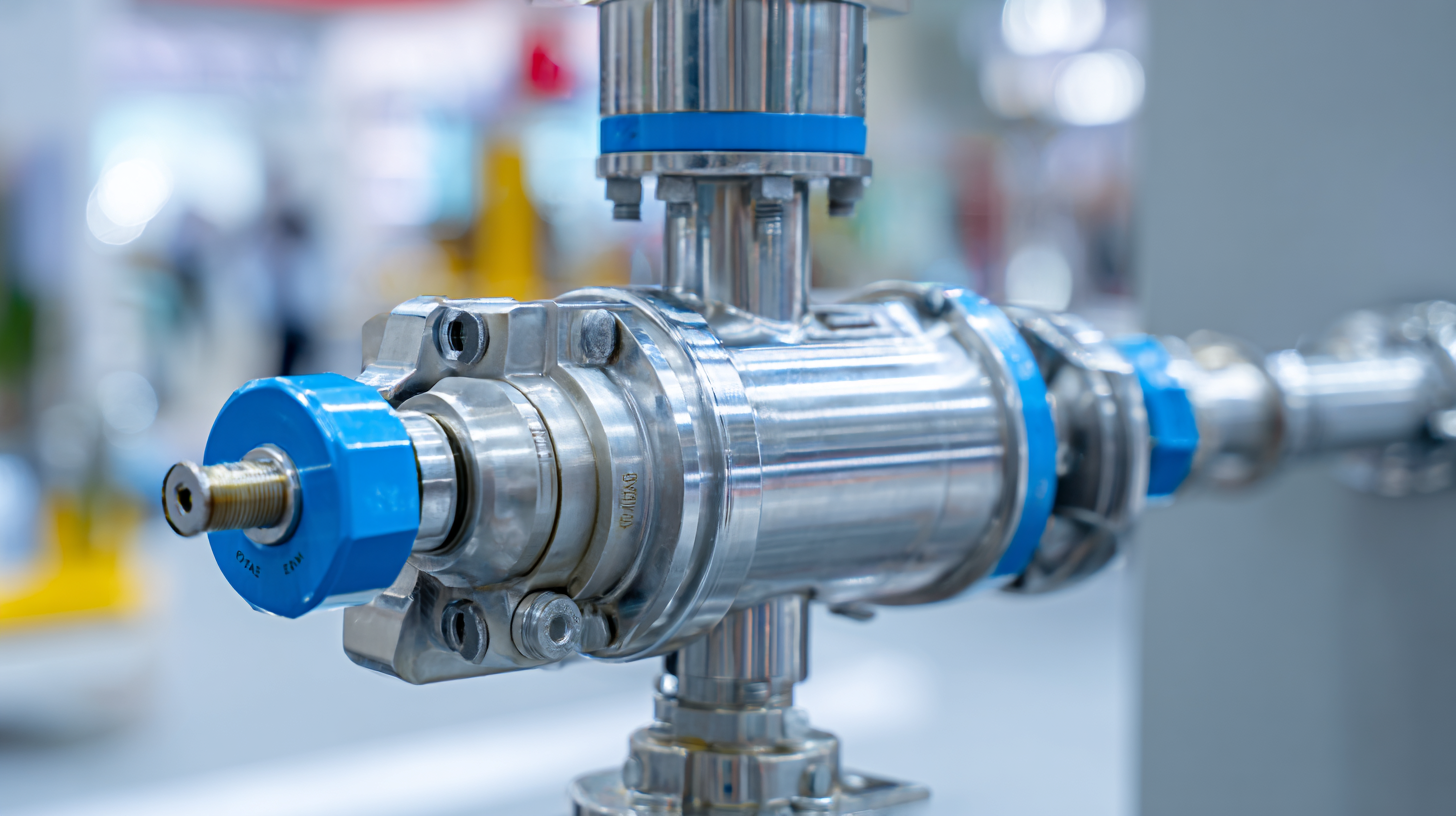

The recent innovations in back pressure valve technology showcased at the 138th Canton Fair 2025 signal a transformative shift in industrial applications. As industries seek greater efficiency and reliability, the integration of advanced back pressure valves is expected to enhance operational performance significantly. According to a 2023 report by MarketsandMarkets, the global back pressure valve market is projected to reach USD 2.5 billion by 2025, growing at a CAGR of 5.8%. This growth reflects the increasing demand for reliable pressure control systems across various sectors including oil and gas, chemical processing, and water management.

The impact of these innovations extends beyond mere functionality; they play a crucial role in optimizing energy use and reducing waste. For instance, the latest designs feature dynamic flow control capabilities that adapt to varying process conditions, which can lead to a 15% reduction in energy consumption for industries relying on pressure control. Furthermore, with the rise of smart factory initiatives, back pressure valves equipped with IoT technologies are paving the way for predictive maintenance strategies, minimizing downtime and enhancing overall system resilience. The future industrial landscape will undoubtedly benefit from these technological advancements, aligning with sustainability goals while improving productivity.

Impact of Back Pressure Valve Innovations on Future Industrial Applications

Related Posts

-

Understanding the Functionality of the Best Back Pressure Valve

-

Common Issues Regarding Back Pressure Regulator Selection and Performance

-

How to Identify Top Quality Manufacturers for the Best Pressure Regulator

-

Understanding Pressure Regulators for Optimal Performance in Industrial Applications

-

How to Optimize Your Systems with Pressure Control Valves for Maximum Efficiency

-

How to Optimize Your Control Valves for Maximum Efficiency and Performance