Essential Checklist for Choosing the Right High Pressure Regulator for Your Industrial Needs

In industrial applications where pressure management is critical, selecting the right high pressure regulator is paramount to ensure safety, efficiency, and performance. According to a report by MarketsandMarkets, the global industrial pressure regulator market is projected to reach $3.2 billion by 2025, reflecting a compound annual growth rate (CAGR) of 5.2% from 2020. This significant growth underscores the importance of understanding the intricacies of high pressure regulators, as they play a vital role in applications ranging from gas distribution to chemical processing.

With various designs and specifications available, industrial operators must prioritize factors such as material compatibility, pressure range, and flow capacity to meet specific operational requirements. This essential checklist will guide you through the top strategies for selecting the right high pressure regulator, ensuring optimal functionality and safety in your industrial applications.

Key Factors to Consider When Selecting a High Pressure Regulator for Industrial Applications

When selecting a high-pressure regulator for industrial applications, several key factors must be considered to ensure optimal performance and safety. According to a report by the International Society for Automation (ISA), nearly 30% of industrial incidents are attributed to the improper selection of pressure control equipment. This highlights the necessity of considering not only the operational pressure range but also the material compatibility with the gases or liquids being handled. For example, regulators made from stainless steel are typically preferred for corrosive environments, as they provide enhanced durability and resistance to chemical reactions.

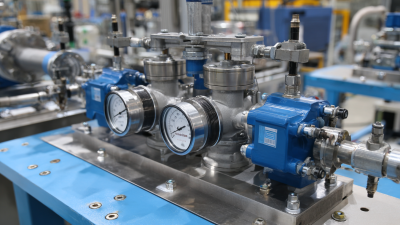

Another critical factor is the flow rate requirements of your application. A 2022 study published in the Journal of Pressure Regulation indicated that regulators with inadequate flow capacities can lead to reduced efficiency and increased downtime. It is essential to match the regulator's specifications with the anticipated flow rates to maintain system integrity. Additionally, evaluating the pressure drop across the regulator under different operating conditions can be vital. Ensuring the regulator can handle peak flow conditions without excessive pressure loss is paramount for maintaining process stability and achieving desired outcomes.

Top 5 Common Mistakes to Avoid in Choosing High Pressure Regulators

Choosing the right high pressure regulator is crucial for ensuring the efficiency and safety of industrial operations. One common mistake is underestimating the pressure and flow requirements of your system. It’s essential to understand your specific application to select a regulator that can handle the necessary pressure range. Failing to do this can lead to poor performance or even system failure.

Another mistake is neglecting to consider the material compatibility of the regulator with the gases or fluids it will regulate. Different materials can react adversely under high pressure or with certain substances, leading to leaks or regulator damage. Make sure to verify that the materials used in the regulator's construction are suitable for your application.

Finally, not paying attention to manufacturer specifications and certifications can also lead to issues down the line. Always check for certifications like ISO or other relevant standards that ensure the regulator meets safety and performance benchmarks. By avoiding these mistakes, you can make a more informed decision when selecting a high pressure regulator that meets your industrial needs.

Essential Checklist for Choosing the Right High Pressure Regulator

Essential Features for High Pressure Regulators: What You Should Look For

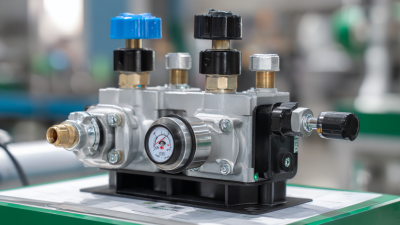

When selecting a high pressure regulator for industrial applications, understanding the essential features is crucial for optimal performance. The first key element to consider is the regulator's pressure range. Ensure that the regulator can accommodate the maximum pressures your operations require and can maintain stability across varying levels. A reliable gauge is also important for monitoring pressure accurately, providing peace of mind while operating under high pressures.

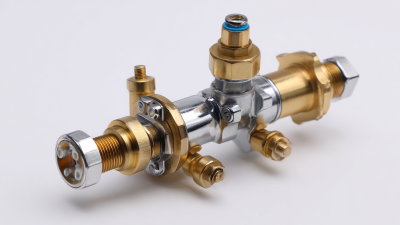

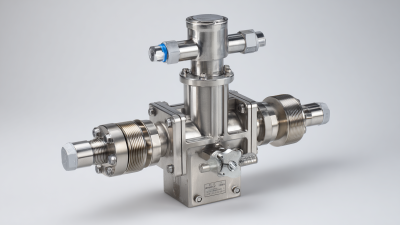

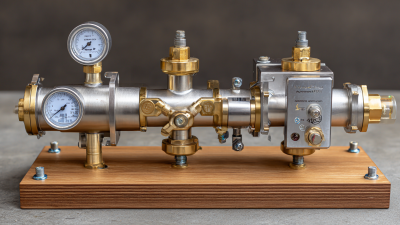

Another critical feature is the material of construction. High pressure regulators are often exposed to harsh environments, so choosing a unit made from durable materials can prevent premature wear and tear. Stainless steel and brass are popular choices due to their resistance to corrosion and ability to withstand extreme conditions. Additionally, look for regulators with adjustable flow rates, allowing for versatility in different operational scenarios.

Tip: Always check for compliance with industry standards. Regulators that meet or exceed safety and quality certifications will not only enhance reliability but also ensure that your operations adhere to safety regulations. Moreover, consider the ease of maintenance. Regulators that are easy to service will minimize downtime and maintain the efficiency of your industrial processes.

Understanding Different Types of High Pressure Regulators and Their Applications

When it comes to selecting the right high-pressure regulator for industrial applications, understanding the various types available is crucial. High-pressure regulators are designed to control the pressure of gases from high-pressure sources, making them essential for processes in industries such as welding, pharmaceuticals, and food manufacturing.

Common types include single-stage and two-stage regulators. Single-stage regulators are typically lighter and more suitable for applications requiring quick adjustments, whereas two-stage regulators provide more stable pressure control and are ideal for applications where precise pressure maintenance is critical.

Moreover, the choice of materials and construction can significantly affect the performance of a high-pressure regulator. Regulators made from stainless steel or brass can offer corrosion resistance and durability for harsh environments. Similarly, adjustable outlet pressure options allow for flexibility in various operational settings. Understanding these factors, along with compatibility with the specific gases and the required flow rates, ensures that industrial operations run smoothly and safely. By assessing these characteristics, operators can make informed decisions and enhance efficiency in their processes.

How to Evaluate Manufacturer Reputation and Product Support for High Pressure Regulators

When choosing a high-pressure regulator for industrial applications, evaluating the reputation of the manufacturer is crucial. Manufacturers with a solid track record often provide assurance regarding product quality and reliability. Look for companies that have maintained long-standing relationships with clients, showcasing their commitment to excellence in manufacturing. Engage in thorough research by checking customer reviews, industry awards, and certifications that validate the manufacturer's reputation. It’s also beneficial to examine any partnerships they may have formed with reputable organizations, as this can be indicative of their standing in the industry.

Product support is equally important when selecting a high-pressure regulator. A manufacturer that offers comprehensive customer service, including technical assistance and warranty options, can significantly enhance your operational efficiency. Additionally, consider their responsiveness to inquiries and how they handle product updates or recalls. A company that invests in after-sales support demonstrates a commitment to ensuring customer satisfaction and proper functioning of their equipment. In a landscape where technology and regulations can change rapidly, having access to reliable product support can be a game changer.

Related Posts

-

How to Identify Top Quality Manufacturers for the Best Pressure Regulator

-

Common Issues Regarding Back Pressure Regulator Selection and Performance

-

Understanding Pressure Regulators for Optimal Performance in Industrial Applications

-

Understanding the Common Issues Faced with Pressure Regulators in Industrial Applications

-

Unveiling China's Leading Electronic Pressure Regulators for Global Procurement Success

-

5 Essential Tips for Choosing the Best Hydrogen Pressure Regulator