Understanding the Common Issues Faced with Pressure Regulators in Industrial Applications

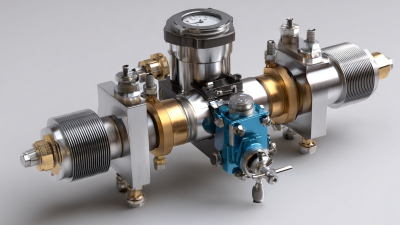

In industrial applications, pressure regulators play a crucial role in maintaining safe and efficient operations across various systems. According to a report from the International Society of Automation, improper regulation of pressure can lead to operational inefficiencies, equipment damage, and safety hazards, costing industries billions annually. Common issues faced with pressure regulators, such as inaccurate pressure readings, valve seat wear, and failure to maintain consistent outlet pressure, can severely disrupt processes. A recent industry survey highlighted that nearly 30% of facilities experienced operational downtime due to pressure regulation failures. By understanding these common challenges, engineers and maintenance teams can implement effective solutions, ensuring reliable performance and enhancing overall system integrity. This blog will provide a comprehensive checklist for identifying and addressing prevalent issues with pressure regulators to foster improved operational efficiency in industrial settings.

In industrial applications, pressure regulators play a crucial role in maintaining safe and efficient operations across various systems. According to a report from the International Society of Automation, improper regulation of pressure can lead to operational inefficiencies, equipment damage, and safety hazards, costing industries billions annually. Common issues faced with pressure regulators, such as inaccurate pressure readings, valve seat wear, and failure to maintain consistent outlet pressure, can severely disrupt processes. A recent industry survey highlighted that nearly 30% of facilities experienced operational downtime due to pressure regulation failures. By understanding these common challenges, engineers and maintenance teams can implement effective solutions, ensuring reliable performance and enhancing overall system integrity. This blog will provide a comprehensive checklist for identifying and addressing prevalent issues with pressure regulators to foster improved operational efficiency in industrial settings.

Common Problem #1: Inaccurate Pressure Readings and Its Causes

In industrial applications, inaccurate pressure readings from pressure regulators can lead to significant operational inefficiencies and safety hazards. One of the primary causes of these inaccuracies is the calibration of the pressure regulator itself. Over time, regulators can drift from their original settings due to wear and tear, environmental factors, or improper installation. When a regulator is not calibrated correctly, it fails to provide accurate pressure outputs, resulting in either excessive pressure, which can damage equipment, or insufficient pressure, which can halt production processes.

Another contributing factor is the presence of contaminants in the gas or liquid being regulated. Particles such as dirt, dust, or residues can clog the regulator’s internal mechanisms, leading to erroneous pressure readings. Additionally, temperature fluctuations can affect the performance of regulators, as changes in temperature may alter fluid properties and pressure dynamics. Regular maintenance and monitoring are essential to ensure accurate performance and to address these common issues promptly, ultimately preserving the integrity of industrial systems and enhancing operational reliability.

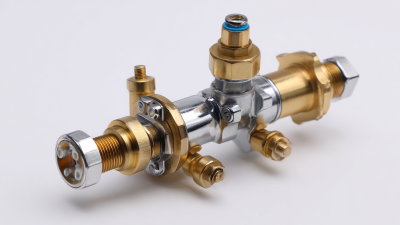

Common Problem #2: Burst or Leakage in Pressure Regulators Explained

Bursting or leakage in pressure regulators is a prominent concern in various industrial applications, potentially leading to safety hazards, operational inefficiencies, and increased operational costs. The complexity of pressure management is highlighted by recent studies which illustrate that improper pressure control plays a significant role in leakage, particularly in water distribution systems. Implementing optimal pressure management practices can effectively mitigate leakage, with reports indicating that managing pressure can reduce leak rates by up to 20% in urban water distribution networks.

In the realm of gas refinery operations, the consequences of pressure regulator failure can be dire, as evidenced by a real explosion incident involving a methane pressure vessel. Root cause analysis (RCA) revealed that inadequate pressure regulation and monitoring systems contributed significantly to the failure. Such incidents underline the importance of rigorous pressure management strategies, which can minimize the likelihood of leaks and bursts. Implementing technologies that enhance pressure control not only safeguards infrastructure but also curtails product loss and environmental risks, reflecting a pivotal shift towards innovative pressure management solutions in the industry.

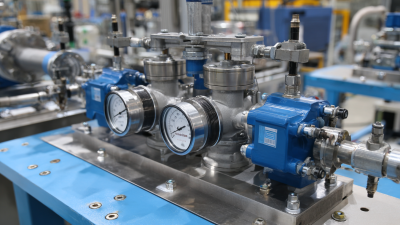

Common Problem #3: Inadequate Flow Control and Its Reasons

In industrial applications, inadequate flow control is a common issue encountered with pressure regulators. This problem often arises in systems such as piston cooling nozzles, where precise flow adjustments are essential. According to research by Zeng in 2022, the flow rate in a piston cooling nozzle can be regulated by modifying the convergent length and inner diameter. These parameters play a crucial role in optimizing flow efficiency and ensuring adequate cooling performance.

Flow control challenges can also stem from various operational conditions, leading to fluctuations in pressure and flow rates that compromise performance. The study highlights that improper sizing of the nozzle, wear and tear of components, and inadequate maintenance can contribute to these issues. Ensuring that these parameters are regularly monitored and adjusted according to the specific demands of industrial processes is vital for maintaining operational efficiency and preventing costly downtimes. Understanding and addressing these flow control challenges is essential for enhancing the reliability and effectiveness of industrial cooling systems.

Common Problem #4: Material Compatibility Issues Leading to Failures

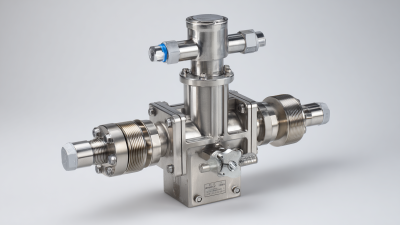

Material compatibility is a critical concern when it comes to pressure regulators used in industrial applications. Often, the materials chosen for construction do not withstand the specific environmental conditions or the substances being regulated. For example, if a pressure regulator is made from a material that is corroded by the fluid it controls, it can lead to premature failure, leaks, or even catastrophic incidents. This is particularly prevalent in industries dealing with harsh chemicals, where the wrong choice of materials can result in significant downtime and costly repairs.

Moreover, temperature fluctuations can exacerbate material compatibility issues. Certain materials may become brittle or expand at extreme temperatures, compromising their structural integrity. It is essential for industries to conduct thorough materials testing and choose regulators made from alloys or plastics that can withstand chemical interaction and temperature variations. Failing to address these compatibility concerns not only jeopardizes equipment longevity but also poses safety risks for personnel. Understanding these nuances can help companies make informed decisions and enhance the reliability of their pressure regulating systems.

Material Compatibility Issues in Pressure Regulators

This chart illustrates the compatibility ratings of various material properties essential for pressure regulators in industrial applications. Ensuring proper material selection helps mitigate failures caused by compatibility issues, thereby enhancing performance and reliability.

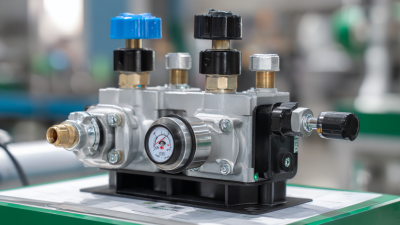

Common Problem #5: Maintenance Neglect and Its Impact on Performance

Neglecting regular maintenance of pressure regulators in industrial applications can lead to significant performance issues and operational inefficiencies. Over time, these critical components encounter wear and tear due to fluctuating pressure levels and environmental conditions. Without systematic checks and timely service, minor issues can escalate into major failures, resulting in costly downtimes and repair expenses. It is essential to establish a consistent maintenance schedule that includes inspections, cleaning, and necessary part replacements to ensure that pressure regulators continue to operate at optimal levels.

Additionally, the consequences of maintenance neglect are often compounded by other factors, such as the increasing demands placed on industrial systems due to the growth of various sectors. For instance, industries that are heavily reliant on pressurized systems may experience reduced output and increased safety risks when pressure regulators fail. Implementing a proactive maintenance culture not only prolongs the life of these devices but also enhances overall system reliability. By prioritizing maintenance, organizations can mitigate risks, improve performance, and maintain a smoother operational flow.

Related Posts

-

Common Issues Regarding Back Pressure Regulator Selection and Performance

-

Unveiling China's Leading Electronic Pressure Regulators for Global Procurement Success

-

How to Identify Top Quality Manufacturers for the Best Pressure Regulator

-

Understanding Pressure Regulators for Optimal Performance in Industrial Applications

-

Innovative Solutions for Effective Temperature Control Valve Integration

-

Innovative Alternatives in High Pressure Gas Regulators for 2025 Technological Advancements