15 Essential Insights About Control Valves for Global Buyers

In the ever-evolving landscape of industrial automation and process control, understanding the intricacies of control valves is paramount for global buyers. Control valves play a crucial role in regulating fluid flow, pressure, and temperature in various systems, ensuring optimal performance and safety. However, selecting the right control valve can present significant challenges, particularly for those unfamiliar with the myriad types and their specific functions.

This blog delves into the common problems associated with various types of control valves, offering essential insights that help buyers navigate potential pitfalls in their selection process. By examining issues such as valve sizing, response time, and compatibility with system requirements, we aim to equip readers with the knowledge necessary to make informed decisions in an increasingly complex market.

Key Considerations for Selecting Control Valve Types Based on Application Requirements

When selecting control valves, understanding the application requirements is critical. Different types of control valves, including PTFE-lined plug valves, serve various functions across industries. The PTFE-lined plug valve market is projected to reach $64.14 million in 2024 and grow to $84.01 million by 2032, reflecting a steady increase driven by widespread adoption in sectors demanding high corrosion resistance. Buyers should carefully evaluate these valves according to their specific operational environments.

When selecting control valves, understanding the application requirements is critical. Different types of control valves, including PTFE-lined plug valves, serve various functions across industries. The PTFE-lined plug valve market is projected to reach $64.14 million in 2024 and grow to $84.01 million by 2032, reflecting a steady increase driven by widespread adoption in sectors demanding high corrosion resistance. Buyers should carefully evaluate these valves according to their specific operational environments.

Tips for selection: First, consider the medium that flows through the valve. The chemical compatibility with the valve material is crucial for preventing leaks or failures. Additionally, assess the required pressure ratings and temperature tolerances of the valve to ensure optimal performance in your application.

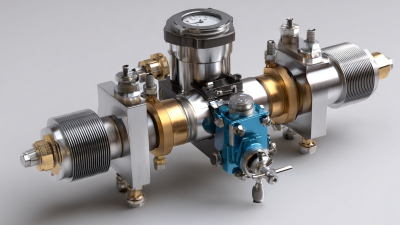

Another important factor is the actuation method. Decide whether electric or pneumatic actuators align better with your system requirements. Proper integration of actuators can enhance control precision, ensuring that the valve operates effectively in response to varying conditions. By aligning valve types with application needs, buyers can significantly improve system efficiency and longevity.

Understanding Flow Characteristics: How They Impact Control Valve Performance

Understanding flow characteristics is crucial for optimizing the performance of control valves across various industries. Flow characteristics define how a valve responds to changes in pressure, temperature, and the characteristics of the fluid being handled. According to a report by the International Society of Automation, up to 50% of all control valve issues can be traced back to improper flow characteristics, which can lead to inefficiencies and increased operational costs. Recognizing the difference between linear, equal percentage, and quick opening flow characteristics allows buyers to select the appropriate valve for their specific application, ensuring better control over processes.

Tip: Always analyze the process requirements before selecting a control valve. Utilize flow simulation software to model how different valve types will perform under varying conditions. This proactive approach can provide insights that save time and resources in the long run.

In addition to flow characteristics, it's essential to consider the valve's Cv (flow coefficient), which quantifies the valve's ability to allow fluid flow. A well-documented study by the American Society of Mechanical Engineers found that optimizing valve sizes based on Cv can improve system efficiency by up to 20%. By ensuring the correct sizing, you minimize pressure drops and enhance overall system reliability.

Tip: Regularly review and adjust the specifications of your control valves in line with any changes in system dynamics over time. This will help maintain optimal performance and prevent unexpected downtime.

Understanding Flow Characteristics Impact on Control Valve Performance

Common Control Valve Designs and Their Features: A Quick Overview

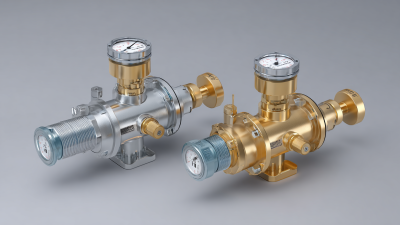

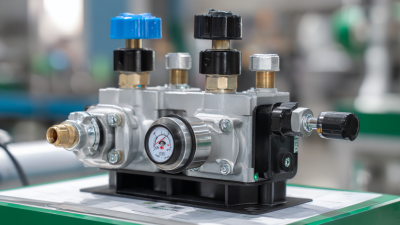

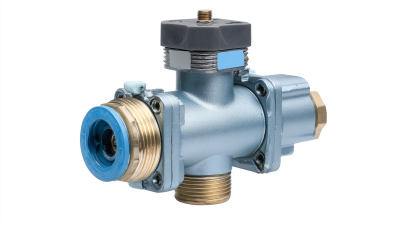

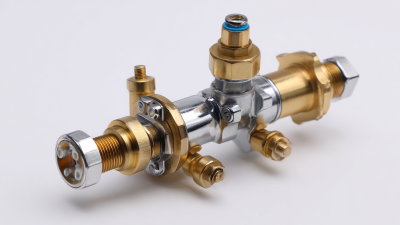

Control valves are vital components in various industrial processes, and understanding their designs and features is crucial for global buyers. Among the most common designs are globe, ball, and butterfly valves. Globe valves are recognized for their exceptional throttling capabilities, making them ideal for applications requiring precise flow control. Their unique shape allows for a more extended flow path, which reduces turbulence and ensures high performance even under varying pressure conditions.

Ball valves, on the other hand, are favored for their quick operation and minimal pressure drop. They feature a spherical disc that provides a straight-through flow path, making them highly efficient for on/off operations. Their simplicity in design contributes to their reliability and longevity in demanding environments. Lastly, butterfly valves offer a compact solution with a quarter-turn operation, suitable for large flow rates. The disc pivots to regulate flow, ensuring a lightweight and space-saving option without compromising performance. Understanding these designs allows buyers to make informed decisions that enhance operational efficiency.

15 Essential Insights About Control Valves for Global Buyers

| Valve Type | Common Features | Applications | Advantages | Disadvantages |

|---|---|---|---|---|

| Globe Valve | Good throttling control, linear flow | Steam, Oil and Gas | Smooth operation, reliability | Higher pressure drop |

| Ball Valve | Quick on/off, low flow resistance | Water, Gas, Oil | Durability, tight sealing | Not suitable for throttling |

| Butterfly Valve | Compact, lightweight, fast operation | HVAC, Water Treatment | Low cost, minimal space | Limited control range |

| Check Valve | Allows flow in one direction | Pipelines, Pump Stations | Prevents backflow | Can cause water hammer |

| Pressure Relief Valve | Automatic pressure control | Chemical Processes, Boilers | Safety mechanism | Maintenance required |

Maintenance Tips to Extend the Lifespan of Control Valves in Industrial Settings

In industrial settings, control valves play a vital role in regulating the flow of fluids, making their maintenance crucial for operational efficiency. According to a report by the International Society of Automation, approximately 80% of control valve failures stem from inadequate maintenance practices. Ensuring that these valves operate optimally can significantly extend their lifespan, which, according to data from the Flow Control magazine, can range anywhere from 10 to 20 years with proper care.

To enhance the longevity of control valves, regular inspection and preventive maintenance are key. A systematic approach includes checking for any signs of wear or corrosion, ensuring that actuator functions are seamless, and calibrating the valve’s position accurately. It's highly recommended to implement a maintenance schedule that aligns with operational demands. Moreover, integrating condition monitoring technologies can proactively detect potential issues, allowing for timely interventions that can mitigate unexpected downtime.

Furthermore, maintaining clean fluid conditions and ensuring appropriate operating pressures can drastically reduce the likelihood of valve failures. According to the Control Valve Handbook, maintaining fluid cleanliness can increase a valve’s operational life by up to 30%. Therefore, investing effort into these maintenance tips will not only save costs but also enhance the reliability and performance of control valves in industrial applications.

Factors Influencing Control Valve Sizing for Optimal System Efficiency

When considering control valve sizing for optimal system efficiency, various factors must be taken into account to ensure peak performance and reliability. According to a report from the Control Valve Market Analysis (2022), the proper sizing of control valves can enhance system efficiency by up to 30%, significantly reducing energy consumption and operational costs. The valve's size, type, and materials used are critical parameters that directly impact flow characteristics and the overall system's responsiveness to demand changes.

Another major influencer is the process fluid properties, including viscosity, temperature, and pressure. Data from the International Society of Automation (ISA) indicates that inconsistencies in fluid characteristics can lead to inefficient valve operation and accidents. For instance, fluids with high viscosity might require oversized valves to maintain adequate flow rates, while high-pressure systems benefit from precise sizing to avoid cavitation risks. Therefore, understanding the characteristics of your application is imperative for global buyers to minimize downtime and increase the lifespan of control valves. Proper analysis and tailored solutions are essential for achieving optimal system efficiency in diverse industrial applications.

Related Posts

-

Leading the Global Market with China's Best Gas Pressure Regulator Innovations

-

Unveiling China's Leading Electronic Pressure Regulators for Global Procurement Success

-

Embracing Industry 2025 Innovations for the Ultimate Water Pressure Regulator Valve Solutions

-

Innovative Alternatives in High Pressure Gas Regulators for 2025 Technological Advancements

-

How to Identify Top Quality Manufacturers for the Best Pressure Regulator

-

The Future of Precision Control: Innovations in Flow Regulator Technology