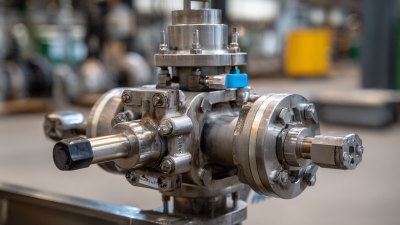

How to Optimize Your Control Valves for Maximum Efficiency and Performance

In the quest for enhanced operational efficiency across various industrial sectors, optimizing control valves has emerged as a critical focal point. According to a recent report by the International Society of Automation, control valves can account for up to 70% of the total pressure drop in a control loop, significantly impacting process efficiency. Moreover, the U.S. Department of Energy estimates that optimizing control valves can save facilities anywhere from 5% to 15% on energy consumption annually. These statistics underscore the importance of employing advanced strategies in the selection, maintenance, and tuning of control valves. By leveraging best practices and modern technologies, businesses can not only improve the performance of control valves but also contribute to substantial cost savings and reduced environmental impact, ultimately driving productivity in today's competitive market landscape.

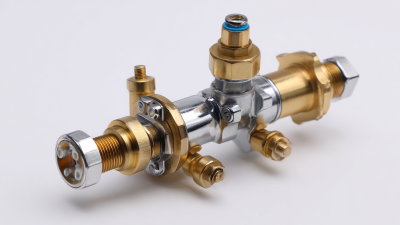

Best Practices for Selecting Control Valves to Minimize Energy Losses

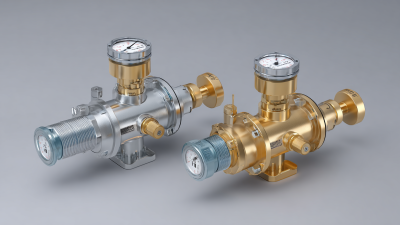

Selecting the right control valves is essential for minimizing energy losses in industrial systems. According to a report by the U.S. Department of Energy, improperly selected or poorly maintained control valves can lead to energy losses of up to 30%. This statistic underscores the importance of evaluating valve performance characteristics such as flow capacity, response time, and pressure drop across the valve. By choosing valves that match the specific requirements of your process, you can significantly reduce unnecessary energy waste and enhance overall efficiency.

Moreover, considerations such as valve trim selection and actuator type can further optimize performance. A recent study published in the Journal of Energy Resources Technology highlights that using advanced actuators can improve control accuracy by up to 15%, resulting in more efficient system operation. When selecting valves, it's crucial to assess the application's flow conditions and pressure variations to ensure the valves not only meet current needs but also have the flexibility to adapt to future changes. By implementing these best practices, facilities can achieve substantial energy savings and improve their operational efficiency.

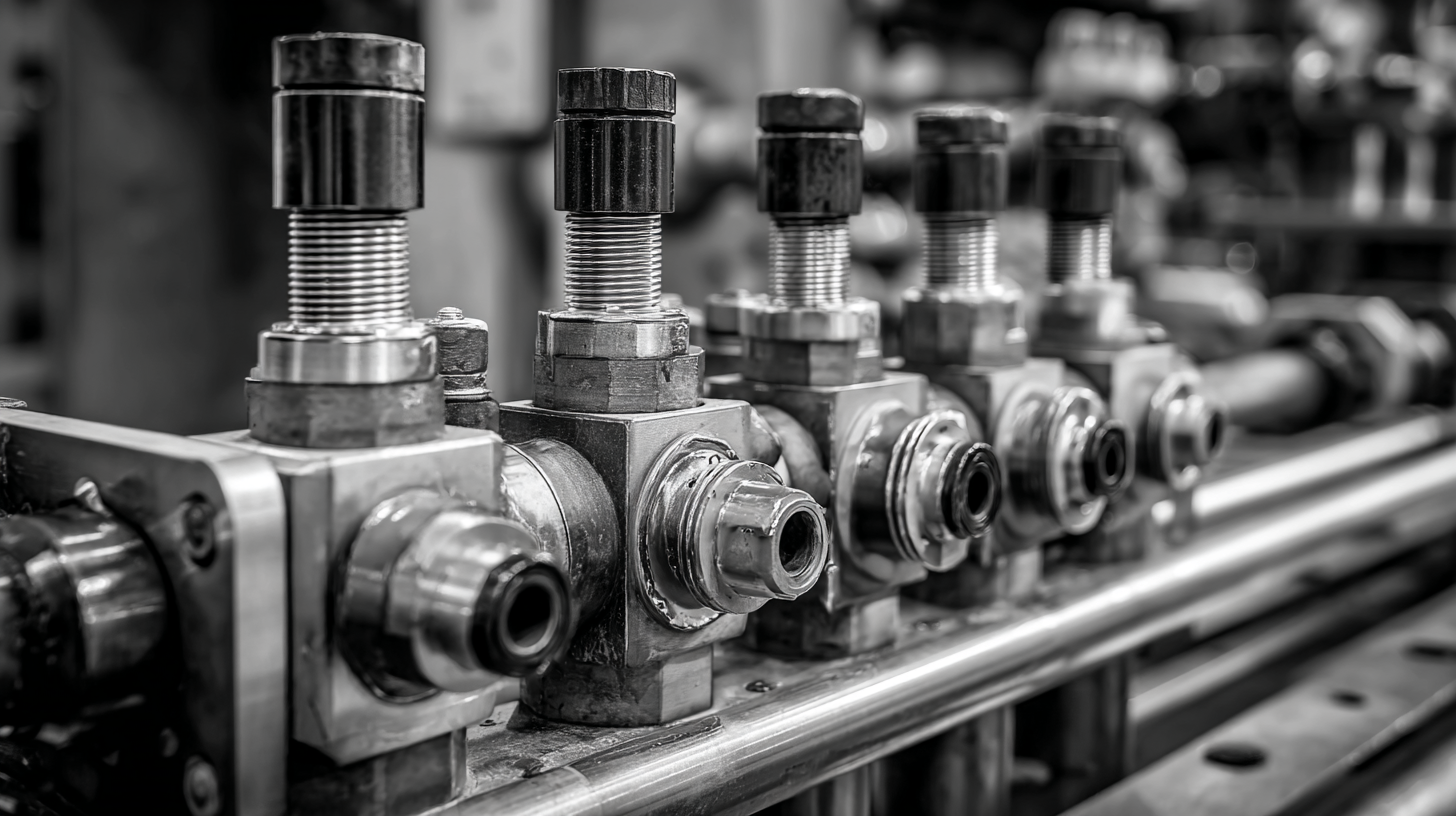

Techniques for Regular Maintenance to Enhance Control Valve Lifespan

Regular maintenance of control valves is essential for enhancing their lifespan and ensuring optimal performance. According to a report from the International Society for Automation (ISA), poorly maintained valves can lead to 30% energy losses and significant process disruptions. By implementing a proactive maintenance strategy, including routine inspections, cleaning, and replacing worn components, organizations can significantly reduce the risk of failure and increase the efficiency of their systems.

One effective technique is to conduct regular diagnostic tests, such as seat leakage tests and response time assessments, to identify potential issues before they escalate. The Valve Repair Council (VRC) suggests that approximately 50% of valve failures are attributable to improper maintenance practices. Additionally, lubricating non-ferrous components and ensuring accurate actuator functionality can extend the operational life of control valves. Incorporating these practices not only minimizes downtimes but also enhances safety and compliance with industry standards, ultimately leading to a more efficient and reliable system.

Key Performance Indicators for Evaluating Control Valve Efficiency

To optimize control valves for maximum efficiency and performance, focusing on key performance indicators (KPIs) is essential. KPIs provide quantitative measures that help evaluate the functionality of control valves within various systems. For instance, metrics such as flow accuracy, response time, and energy consumption are critical in assessing a valve's performance. Establishing a framework that includes these KPIs allows engineers to identify inefficiencies and implement targeted improvements in real-time operations.

Tips: Regularly monitor flow rates and compare them against the designed specifications to ensure that the control valves are functioning optimally. Additionally, leverage advanced techniques such as machine learning models to predict potential efficiency drops and preemptively address issues. This proactive approach aids in maintaining peak performance without incurring excessive operational costs.

Moreover, integrating feedback mechanisms can enhance the evaluation process. For example, using data-driven insights from occupant experiences in smart buildings can inform adjustments to control valve settings, thereby improving indoor environmental quality. As demonstrated in recent studies, incorporating user feedback into KPI development leads to a more comprehensive understanding of operational performance, facilitating a more responsive control system.

How to Optimize Your Control Valves for Maximum Efficiency and Performance - Key Performance Indicators for Evaluating Control Valve Efficiency

| Parameter | Optimal Value | Current Value | Performance Score (%) | Comments |

|---|---|---|---|---|

| Flow Coefficient (Cv) | 50 | 45 | 90 | Slightly below optimal |

| Leakage Rate | 0.05% | 0.07% | 85 | Above acceptable limit |

| Response Time | 2 seconds | 2.5 seconds | 80 | Delay in actuation |

| Temperature Range | -20 to 120 °C | -15 to 115 °C | 88 | Near optimal range |

| Pressure Drop | 10 bar | 12 bar | 75 | Exceeds optimal limits |

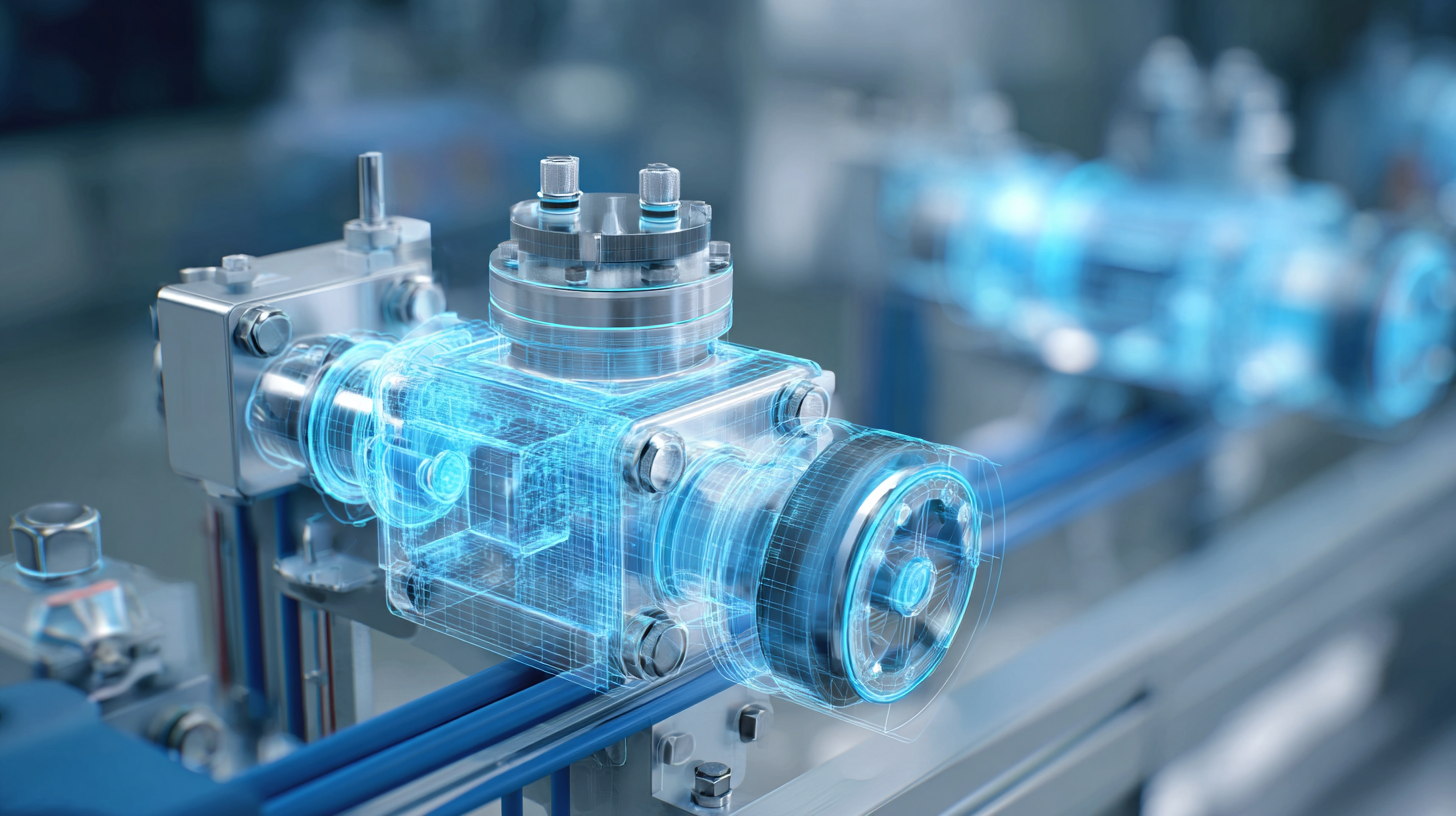

Innovative Technologies for Monitoring and Optimizing Control Valve Performance

Innovative technologies for monitoring and optimizing control valve performance have revolutionized how industries manage fluid flow and process control. Recent reports indicate that implementing advanced monitoring systems can enhance valve performance by up to 30%, leading to significant reductions in energy consumption and operational costs. Utilizing digital twin technology, for example, allows operators to simulate and analyze valve behavior under various conditions, ultimately improving decision-making and predictive maintenance.

**Tip:** Invest in smart sensors that provide real-time data on valve position, flow rate, and pressure. This information can help identify inefficiencies and facilitate timely interventions, preventing costly downtime.

Moreover, the integration of machine learning algorithms into control systems enables predictive analytics to foresee potential failures and performance degradation. A study published in the Journal of Process Control highlighted that plants utilizing predictive maintenance strategies experienced a 20% decrease in unplanned outages. By continuously analyzing performance data, companies can implement targeted optimizations to adapt to changing process demands.

**Tip:** Regularly update your monitoring systems to include the latest analytical tools, ensuring that your control valves operate at their peak efficiency and reliability.

Strategies for Implementing Data-Driven Decision-Making in Valve Management

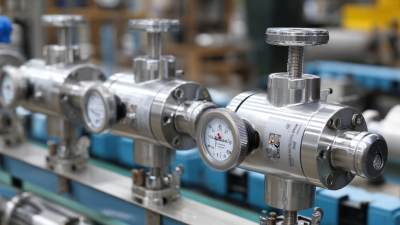

Implementing data-driven decision-making in valve management is crucial for optimizing control valves and enhancing overall system performance. By harnessing data analytics and real-time monitoring, facility managers can identify inefficiencies, predict maintenance needs, and make informed adjustments that boost operational efficiency.

**Tip:** Start by integrating IoT sensors to gather data on flow rates, pressure changes, and valve performance. This information can be utilized to develop predictive maintenance schedules and identify potential problems before they escalate.

Another strategy involves leveraging advanced software for data analysis. This allows for the modeling of various scenarios, helping to determine the optimal settings for each valve under different operating conditions. Understanding the interplay of various factors can lead to more effective control strategies and improved valve response times.

**Tip:** Regularly review the performance data alongside the maintenance history to fine-tune your valve management strategies. Continuous adjustments based on solid data insights can significantly prolong the lifespan of your control valves and enhance system reliability.

Control Valves Efficiency Optimization: Performance Comparison

This chart compares the efficiency of different control valves (A to E) based on performance data collected. The goal is to identify which valve offers the highest efficiency to guide future optimization strategies.

Related Posts

-

Understanding the Common Issues Faced with Pressure Regulators in Industrial Applications

-

How to Optimize Your System with Swagelok Back Pressure Regulators

-

Leading the Global Market with China's Best Gas Pressure Regulator Innovations

-

Understanding the Functionality of the Best Back Pressure Valve

-

8 Proven Best Practices for Optimizing Natural Gas Regulators Performance

-

How to Identify Top Quality Manufacturers for the Best Pressure Regulator