How to Optimize Your Systems with Pressure Control Valves for Maximum Efficiency

In the ever-evolving industrial landscape, optimizing systems for maximum efficiency is imperative for sustaining competitive advantage. One critical component in this optimization process is the pressure control valve, which plays a pivotal role in regulating fluid flow and maintaining desired pressure levels within various systems. According to a recent report by the Global Market Insights, the pressure control valve market is projected to exceed USD 3 billion by 2027, driven by the growing demand for automation and process optimization across multiple sectors, including oil and gas, water management, and manufacturing.

Implementing advanced pressure control valves not only enhances performance but also significantly reduces energy consumption and operational costs, making it a key focus for industries aiming to bolster efficiency and sustainability. In this blog, we delve into the best strategies to leverage pressure control valves for optimizing your systems, guaranteeing you stay ahead in a challenging market.

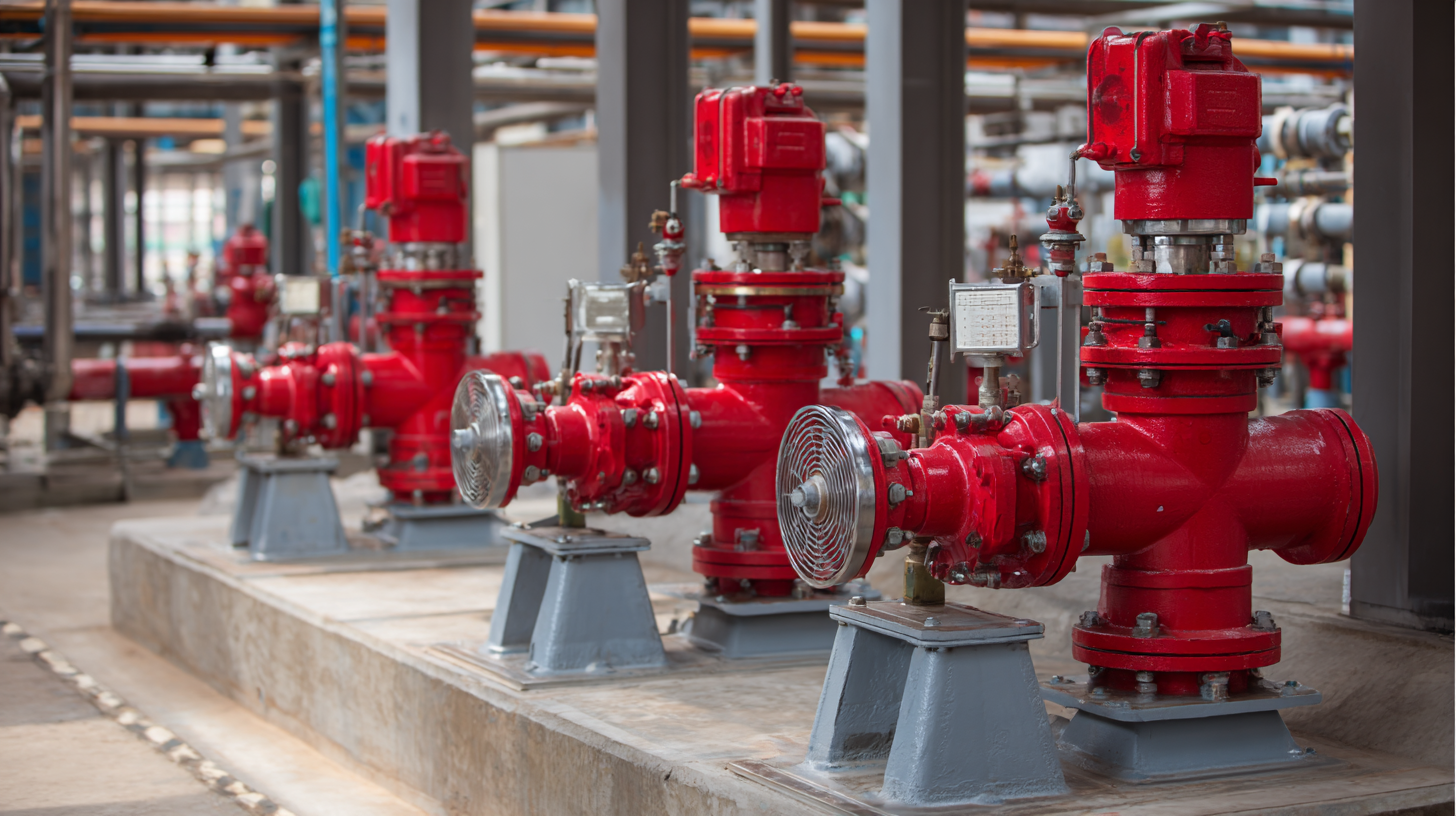

Maximizing Efficiency: Understanding the Role of Pressure Control Valves in System Optimization

Pressure control valves play a crucial role in optimizing system efficiency across various industrial applications. These components regulate the pressure within systems, ensuring that operations remain within safe and optimal limits. By maintaining consistent pressure levels, pressure control valves prevent the system from experiencing fluctuations that can lead to energy wastage and potential equipment damage. Understanding their function enables engineers to design systems that maximize performance while minimizing costs.

Incorporating pressure control valves into system design not only enhances efficiency but also extends the lifespan of equipment. By mitigating pressure spikes and drops, these valves help in reducing wear and tear on machinery, leading to lower maintenance costs over time. Additionally, their ability to adjust flow rates according to demand ensures that resources are used judiciously, thereby contributing to sustainability in operations. Overall, effective integration of pressure control valves is essential for achieving optimal system performance and reliability.

Key Industry Statistics: The Impact of Pressure Control Valves on Operational Performance

Pressure control valves are critical components in various industrial systems, playing a significant role in operational efficiency. According to a recent report by Research and Markets, industries that implement efficient pressure control systems can increase their operational performance by up to 25%. This improvement is not only a testament to the effectiveness of pressure control valves but also highlights their importance in minimizing energy consumption and reducing operational costs.

Furthermore, a survey conducted by the Fluid Power Journal revealed that companies that invested in advanced pressure control technologies saw a 30% reduction in system failures and maintenance costs. These statistics emphasize how pressure control valves can lead to enhanced reliability and uptime for systems, ultimately translating to increased productivity. With the current industry trend towards automation and smart technology integration, optimizing systems with pressure control valves is essential for achieving maximum operational efficiency and driving success in a competitive landscape.

How to Optimize Your Systems with Pressure Control Valves for Maximum Efficiency - Key Industry Statistics

| Metric | Value | Impact on Efficiency (%) |

|---|---|---|

| Reduced Energy Costs | 15% savings | 20% |

| Increased System Lifespan | 50% longer | 15% |

| Improved Process Control | Up to 98% accuracy | 30% |

| Reduction in Downtime | 40% decrease | 25% |

| Waste Reduction | 10% less waste | 18% |

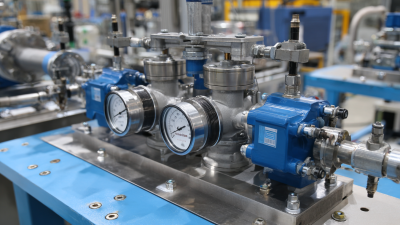

Best Practices for Implementing Pressure Control Valves to Enhance System Efficiency

Implementing pressure control valves is essential for enhancing the efficiency of various systems, particularly in industrial settings. These valves play a crucial role in regulating pressure levels, ensuring that systems operate within their optimal range. One best practice is to conduct a thorough assessment of your system's requirements before installation. Understanding the specific pressures and flow rates needed allows for the selection of the right type of valve, whether it be a direct-acting or pilot-operated design. Utilizing sensors that provide real-time data on pressure and flow can improve decision-making and reduce the risk of equipment failure.

Another key practice in enhancing system efficiency is regular maintenance and calibration of pressure control valves. Routine checks can identify wear or blockage that may hinder performance. Implementing a scheduled maintenance program not only prolongs the lifespan of the valves but also ensures consistent operation, minimizing downtime and unexpected costs. Additionally, integrating automation technology can streamline the control process, allowing for instantaneous adjustments to pressure levels based on real-time conditions, ultimately leading to more efficient energy usage and system reliability.

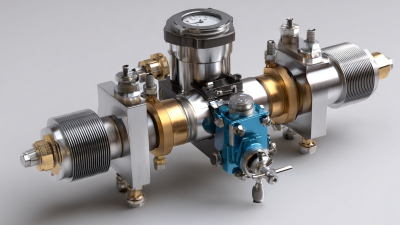

Comparative Analysis: Traditional vs. Advanced Pressure Control Valves in Industrial Applications

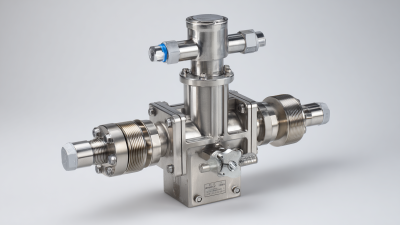

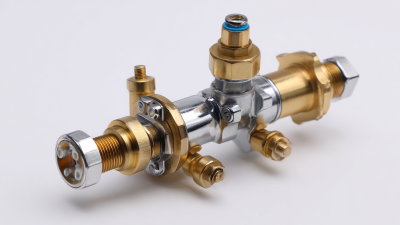

When evaluating pressure control valves for industrial applications, a comparative analysis between traditional and advanced options can reveal significant differences in performance and efficiency. Traditional pressure control valves usually rely on mechanical components, which can lead to slower response times and less precise pressure regulation. These valves are known for their robust design but often struggle with adaptability to varying system demands, leading to potential inefficiencies and increased wear over time.

In contrast, advanced pressure control valves are designed with modern technologies, such as electronic controls and smart sensors. These innovations enable quicker adjustments and fine-tuning capabilities, resulting in more accurate pressure regulation and enhanced system performance. Additionally, advanced valves can often integrate with automation systems, facilitating real-time monitoring and adjustments based on dynamic operating conditions. Industries that prioritize efficiency and cost-effectiveness should consider these advanced options, as they can significantly reduce energy consumption and improve overall system reliability.

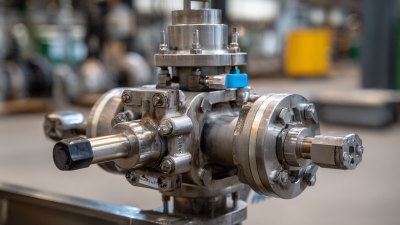

Future Trends: Innovations in Pressure Control Valve Technology Shaping Process Efficiency

The evolution of pressure control valve technology is driving significant improvements in process efficiency across various industries. Recent data from a study conducted by MarketsandMarkets suggests that the pressure control valve market is projected to grow from $5.1 billion in 2021 to $7.3 billion by 2026, reflecting a compound annual growth rate (CAGR) of 7.5%. This growth is largely attributed to advancements in automation and digitalization, which are enabling more precise control over pressure systems, reducing energy consumption, and enhancing overall operational performance.

Innovations such as smart valves equipped with IoT capabilities are gaining traction, allowing for real-time monitoring and adaptive control. A report by Grand View Research highlights that smart valve technology can lead to energy savings of up to 20%, significantly reducing operational costs while improving process efficiency. Additionally, the integration of machine learning algorithms in valve operations is set to optimize performance further by predicting maintenance needs and minimizing downtime, a critical factor in industries like oil and gas, where unplanned outages can result in substantial economic losses. As these technologies continue to advance, they will undoubtedly shape the future landscape of pressure control systems, embracing sustainability and efficiency like never before.

Related Posts

-

Common Issues Regarding Back Pressure Regulator Selection and Performance

-

How to Identify Top Quality Manufacturers for the Best Pressure Regulator

-

Understanding the Functionality of the Best Back Pressure Valve

-

Understanding Pressure Regulators for Optimal Performance in Industrial Applications

-

Understanding the Common Issues Faced with Pressure Regulators in Industrial Applications

-

Innovative Alternatives in High Pressure Gas Regulators for 2025 Technological Advancements