Understanding Pressure Regulators for Optimal Performance in Industrial Applications

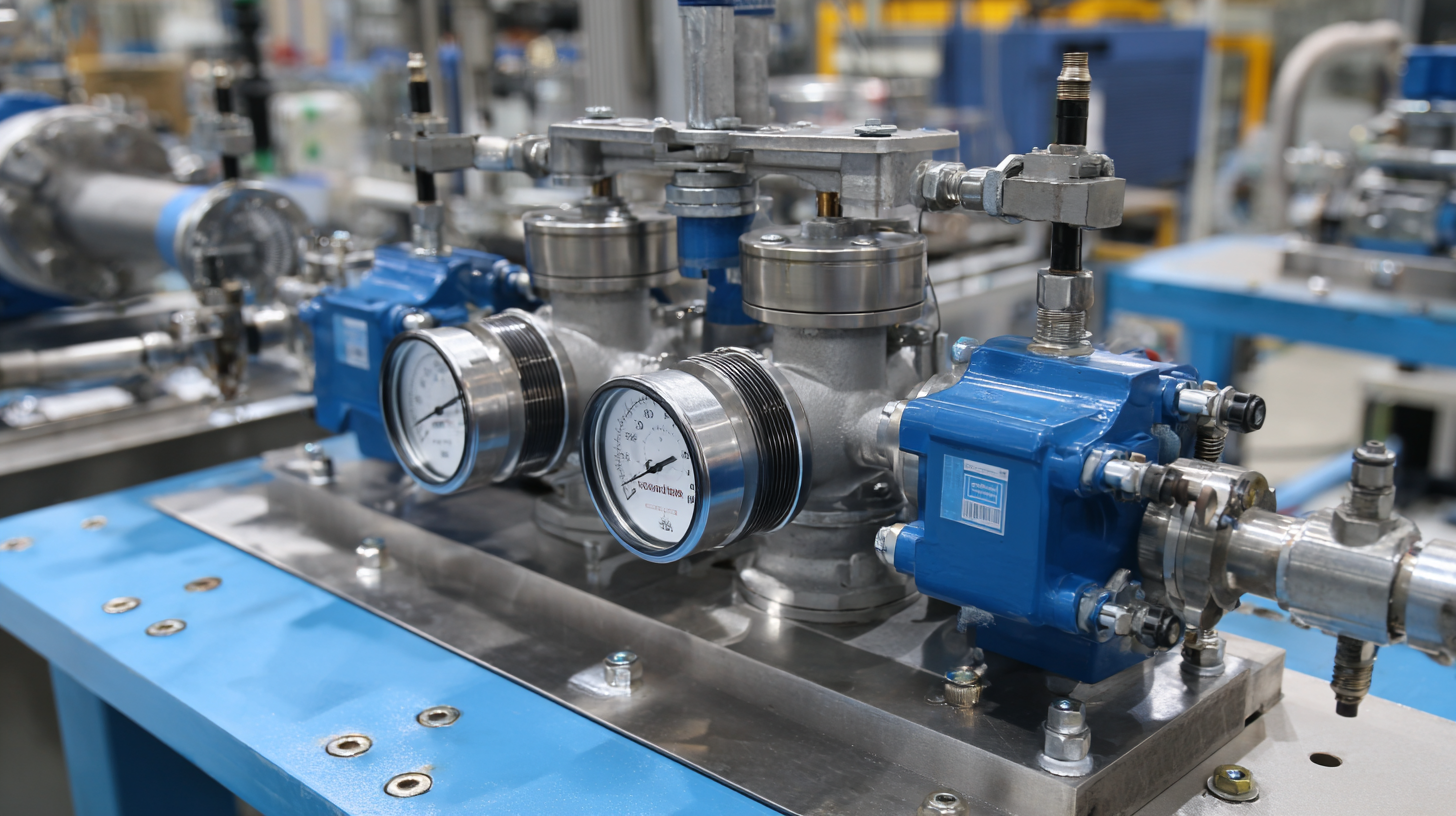

In the realm of industrial applications, the importance of maintaining optimal performance cannot be overstated, and one key component that plays a critical role in achieving this is the pressure regulator. Designed to control and stabilize pressure levels within various systems, pressure regulators ensure that processes run smoothly without the risk of pressure fluctuations that can lead to inefficiencies or equipment damage. This guide aims to unravel the complexities of pressure regulators, exploring their functionality, types, and best practices for implementation. Understanding how to select and utilize these devices effectively can be the difference between a well-functioning system and one fraught with operational challenges. Whether you are new to the concept of pressure regulation or seeking to enhance your existing knowledge, this comprehensive overview will provide valuable insights into optimizing your industrial applications.

Understanding Pressure Regulators: 5 Key Specifications Impacting Performance

Understanding the performance of pressure regulators in industrial applications is crucial for ensuring optimal functionality and safety.

Five key specifications significantly influence their effectiveness: pressure range, flow capacity, accuracy, response time, and temperature compatibility.

For instance, a robust pressure regulator should operate reliably within a specified pressure range, typically between 0-300 psi. This allows industries to maintain a stable output while accommodating fluctuations in input pressures.

Moreover, flow capacity is equally essential, as higher capacities enable better performance in systems requiring rapid pressure adjustments.

Studies show that a flow capacity of 50 SCFM can enhance the efficiency of compressed air systems significantly.

Additionally, accuracy, particularly in sensitive applications, cannot be overlooked; regulators with an accuracy of ±1% can prevent costly errors in processes such as chemical manufacturing.

With the right specifications, pressure regulators can maintain optimal conditions, thus facilitating processes that require precise pressure control and contributing to overall operational efficiency.

Top 3 Industries Requiring Precision in Pressure Regulation

In the realm of industrial applications, precision in pressure regulation is essential for operational efficiency and safety. Three key industries that particularly benefit from optimal pressure regulation are oil and gas, pharmaceuticals, and food processing. According to the International Energy Agency (IEA), the oil and gas sector accounts for approximately 55% of global energy demand, where maintaining consistent pressure in pipelines and refineries is critical to ensure safety and compliance with environmental regulations. A minor pressure fluctuation can lead to catastrophic failures, making advanced pressure regulators indispensable for this industry.

Similarly, the pharmaceutical industry demands stringent pressure control to meet regulatory standards. The U.S. Food and Drug Administration (FDA) mandates that manufacturing processes maintain a specific pressure range to ensure sterility and efficacy in drug products. Failure to regulate pressure accurately can result in compromised product quality, leading to costly recalls. Reports indicate that an estimated 20% of pharmaceutical production lines experience production downtime due to improper pressure regulation, highlighting the need for precision in this sector.

Lastly, the food processing industry relies heavily on pressure regulators to ensure product safety and quality. The Global Food Safety Initiative (GFSI) emphasizes that pressure control is vital in processes such as pasteurization and packaging. Ineffective pressure management can lead to contamination or spoilage, causing significant financial losses. In fact, studies show that poor pressure regulation can account for up to 15% of operational inefficiencies in food processing plants, underscoring the critical importance of reliable pressure regulation systems in safeguarding public health and optimizing industrial performance.

5 Reasons Why Pressure Regulation Minimizes Equipment Downtime

In industrial applications, pressure regulators play a crucial role in maintaining optimal equipment performance and minimizing downtime. One significant reason for this is the ability of pressure regulators to ensure consistent pressure levels, which is vital for the efficient operation of pneumatic and hydraulic systems. According to a report by the International Society for Automation (ISA), systems that operate within their specified pressure ranges can enhance productivity by up to 20%, significantly reducing the likelihood of unexpected equipment failures.

Moreover, pressure regulation contributes to extending the lifespan of machinery by preventing pressure fluctuations that can lead to wear and tear. A study published in the Journal of Industrial Engineering highlights that companies implementing robust pressure control systems experienced a 30% reduction in maintenance costs. This is partly due to the prevention of cavitation and other pressure-related issues that can damage components over time. By investing in high-quality pressure regulators, industries can optimize their operations while ensuring that their equipment remains reliable, ultimately translating to lower operational costs and increased profitability.

4 Tests to Ensure Optimal Pressure Regulator Performance in the Field

When it comes to maintaining optimal performance of pressure regulators in industrial applications, conducting regular tests is essential. One of the most critical tests is the **leak test**, which ensures that there are no unwanted escapes of gas or fluid. Regularly checking for leaks not only preserves system integrity but also enhances safety. Tip: Utilize a soap solution or ultrasonic leak detector to quickly identify leaks.

Another important assessment is the **functionality test**, which examines the regulator's ability to maintain stable output pressure under various load conditions. It's vital to simulate different operational scenarios to ensure the regulator performs efficiently. Tip: Maintain a log of performance data during these tests to track any aberrations over time.

Finally, **pressure calibration** is indispensable for verifying accurate readings and ensuring the system operates within designated parameters. Calibration should be performed in accordance with manufacturer specifications and industry standards. Tip: Schedule these calibrations regularly and keep the calibration certificates accessible for compliance verification. By implementing these tests, businesses can ensure that their pressure regulators operate smoothly, enhancing overall productivity.

The 6 Benefits of Regular Maintenance for Pressure Regulators in Industrial Settings

Regular maintenance of pressure regulators in industrial settings offers numerous benefits that contribute significantly to operational efficiency. According to a report from the American Society of Mechanical Engineers (ASME), routine inspections can reduce downtime by up to 30%, allowing for more consistent production schedules. This maintenance includes checking for leaks, ensuring proper calibrations, and replacing worn components, all of which contribute to enhanced reliability and safety in industrial processes.

Furthermore, data from the International Society of Automation (ISA) indicates that regular maintenance can improve the lifespan of pressure regulators by as much as 50%. This not only reduces the frequency of costly replacements but also minimizes the risk of failures that can lead to hazardous situations. In addition, maintaining optimal pressure settings through regular checks can enhance energy efficiency, with estimates suggesting energy savings of 10-20% in optimized systems. Such proactive measures ensure that pressure regulators perform effectively, supporting overall production goals and maintaining compliance with safety standards.